| 0 Comments | Enkor

Cathodic protection systems provide long-term solutions against corrosion in pipelines, storage tanks, marine structures, and other industrial facilities. In these systems, anode selection is critical for both efficiency and service life. Choosing the wrong anode not only reduces system performance but also increases maintenance costs.

In this article, we will examine the technical properties, applications, advantages, and disadvantages of magnesium, zinc, and aluminum anodes.

The Role of Anodes in Cathodic Protection Systems

In cathodic protection, anodes can act either as sacrificial anodes (galvanic) or as auxiliary anodes in impressed current systems.

-

Sacrificial anodes: More active metals that corrode preferentially, protecting the structure.

-

Impressed current anodes: Powered by a rectifier and external current source.

In this article, we focus on galvanic (sacrificial) anodes. The correct choice of anode depends on the environmental resistivity, polarization requirements, and project lifetime.

For more background, see: What is Cathodic Protection? Why is it Important?

Magnesium Anodes

Technical Properties:

-

Anode potential: approx. –1.55 V (–1.75 V for high potential types)

-

Driving potential vs. steel: ~700–900 mV

-

Capacity: ~1,100 Ah/kg (≈50% efficiency)

-

Consumption rate: ~7.9 kg per A·year

Applications:

-

Freshwater environments

-

High-resistivity soils

-

Systems requiring rapid initial polarization

Advantages: Fast polarization, effective in poorly coated or bare surfaces.

Disadvantages: Rapidly consumed in seawater, less economical for large-scale projects.

Zinc Anodes

Technical Properties:

-

Anode potential: ~–1.10 V

-

Driving potential vs. steel: ~250 mV

-

Capacity: ~738 Ah/kg (≈90% efficiency)

-

Consumption rate: ~11.8 kg per A·year

Applications:

-

Seawater environments

-

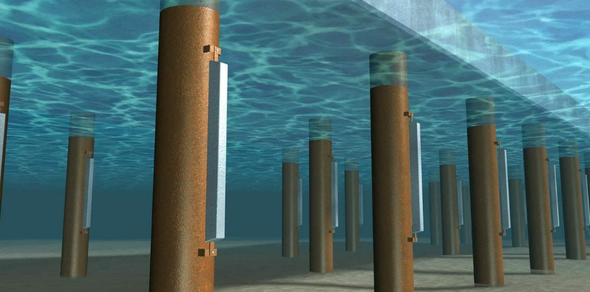

Ships, port piles, offshore platforms

Advantages: Stable performance, long service life, low maintenance.

Disadvantages: Ineffective in freshwater, capacity decreases at temperatures above 60 °C.

Aluminum Anodes

Technical Properties:

-

Anode potential: ~–1.10 V

-

Driving potential vs. steel: ~250 mV

-

Capacity: ~2,670 Ah/kg (≈90% efficiency)

-

Consumption rate: ~3.5 kg per A·year

Applications:

-

Seawater environments

-

Offshore platforms, ports, ship hulls

Advantages: Lightweight (easy handling), high capacity, long life, cost-effective.

Disadvantages: May risk passivation in very low temperature and low-conductivity environments; indium-alloyed types are preferred for stable performance.

Learn more: Cathodic Protection for Steel Piles in Marine Structures

Which Anode Should Be Used?

-

Freshwater / high-resistivity soils: Magnesium

-

Seawater (traditional applications): Zinc

-

Marine structures & large-scale projects: Aluminum (indium-alloyed)

Other factors such as coating condition, required service life, and logistics should also be considered.

Comparison Table

| Property | Magnesium | Zinc | Aluminum |

|---|---|---|---|

| Anode Potential (CSE) | –1.55 V (–1.75 V HP) | –1.10 V | –1.10 V |

| Driving Potential vs. Steel | 700–900 mV | 250 mV | 250 mV |

| Capacity (Ah/kg) | ~1,100 | ~738 | ~2,670 |

| Efficiency | 50% | 90% | 90% |

| Consumption per A·year | ~7.9 kg | ~11.8 kg | ~3.5 kg |

| Recommended Medium | Freshwater / high-resistivity soils | Seawater | Seawater (preferred) |

Conclusion

Correct anode selection in cathodic protection systems directly determines system performance and lifetime.

-

Magnesium: Best for freshwater and high-resistivity soils

-

Zinc: Reliable traditional solution for seawater

-

Aluminum: Lightweight, high-capacity, and cost-effective modern choice

Contact us for professional support in selecting the most suitable anode for your project: Contact

Frequently Asked Questions (FAQ)

Which anode lasts the longest in cathodic protection?

Aluminum anodes, with a capacity of about 2,670 Ah/kg, last much longer than zinc or magnesium. They are ideal for large-scale, long-term projects.

Why is magnesium anode preferred in freshwater?

Magnesium anodes provide a high driving potential, which is required to deliver sufficient current in high-resistivity freshwater and soil environments.

What is the difference between zinc and aluminum anodes?

Zinc anodes have been the traditional choice in seawater. Aluminum anodes, however, provide the same potential at a lighter weight and higher capacity, making them more economical and practical in modern marine applications.

How is anode selection made in cathodic protection?

Selection depends on resistivity, temperature, service life, coating condition, and overall cost:

-

Freshwater/high-resistivity → Magnesium

-

Seawater (traditional) → Zinc

-

Large-scale marine projects → Aluminum (indium-alloyed)

How is anode life calculated?

Anode life is calculated based on capacity (Ah/kg), efficiency, system current demand (A), and required design life. Correct engineering design ensures reliable protection for the intended period.