Construction and Cathodic Protection Services

Schedule an appointment today using our online form and benefit from our expert consultation for your projects

Strengthening Tomorrow, Protecting Today

At Enkor Construction and Corrosion Technologies Ltd. Co., we are dedicated to building your future while protecting the structures of today with sustainable solutions. Our advanced technology and innovative engineering approaches ensure your projects are realized with confidence. We provide high-standard, eco-friendly services in both construction and corrosion protection, guaranteeing the durability and longevity of your structures. Guided by the principle of sustainability, we work to add value to the future.

Looking for quality and reliable services?

Contact Enkor and discover the best solutions

For more information, check out our Contact section

Frequently Asked Questions

Help and support details

Enkor offers a wide range of services in construction and corrosion technologies. These include concrete cutting, chemical anchorage, epoxy injection, and various corrosion technology services such as cathodic protection surveys, project design, and implementation.

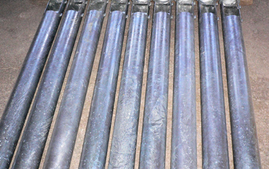

We produce all necessary materials for cathodic protection systems, including:

- Magnesium, aluminum/indium, and zinc anodes

- Cu/CuSO4, Ag/AgCl, and zinc reference electrodes

- Test posts (junction boxes)

- Transformer rectifier (TR) units

- MMO-coated titanium auxiliary anodes

Cathodic protection is a method used to protect metal structures from corrosion by making them the cathode of an electrochemical cell. This technique is crucial because it significantly extends the lifespan of metal structures and enhances their safety. By preventing corrosion, cathodic protection minimizes maintenance costs and reduces the risk of structural failures. It is widely used in various industries, including pipelines, storage tanks, and marine applications, to ensure the durability and reliability of critical infrastructure.

Cathodic protection is applied in projects involving marine structures, pipelines, tanks, and bridges that are at high risk of corrosion. This system is ideal for extending the lifespan and ensuring the safety of these metal structures.

The installation of cathodic protection begins with preliminary studies to determine protection requirements and select suitable anodes. After installation, the system's performance is tested and then activated.

Cathodic protection systems are monitored through regular measurements and performance evaluations. Anode currents, potential measurements, and other parameters are checked. System components are adjusted or replaced as needed.

A reference electrode is used in cathodic protection systems to measure the potential of metal structures. Types include Cu/CuSO4, Ag/AgCl, and Zn. They are used during measurements to monitor the protection status of the structure.

Our Mission

Our mission is to contribute to the successful completion of complex projects by providing our clients with value-added engineering, procurement, and construction solutions..

View MoreContact Us

For inquiries about our services, consultations, or support needs, we are here to assist you. Visit us, call us, or send an email. We will respond promptly during our working hours. Your satisfaction and success are our priorities.

Contact UsProducts

About Products